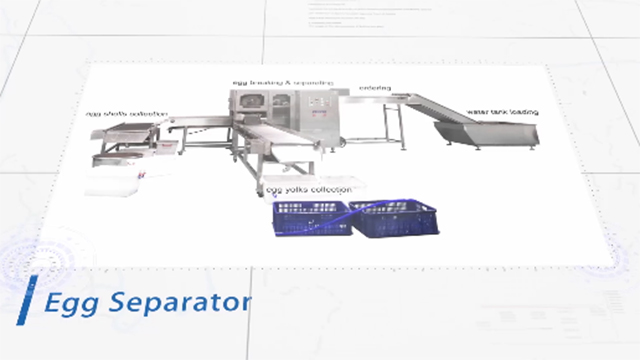

Egg Separator

ZENYER designs egg separators specifically for food processing companies that use egg liquids in their products. We have designed a number of different egg separator models based on an array of customer requirements for productivity and egg liquid requirements. We have models used specifically for separating eggshells and egg liquids, and models for separating the shells, egg whites, and egg yolks. We recommend choosing our egg graders and egg washers for a higher production efficiency.

-

- 500 Egg Centrifuge

Capacity: 20,000 eggs/hour

Function: Breaking, separating eggshell and liquid (yolk and egg white not separated)

Dimension (L×W×H): 1.8×0.68×1.15 M

Materials: Stainless steel

-

- 501A Egg Separator

Capacity: 3,000 eggs/hour

Function: Breaking, separating eggshells, yolks and egg whites

Dimension (L×W×H): 1.38×0.85×1.18 M

Materials: Stainless steel

-

- 501B Egg Separator

Capacity: 8,000 eggs/hour

Function: Breaking, separating egg whites and yolks

Dimension (L×W×H): 3×1.13×1.4 M

Materials: Stainless steel

Voltage: 220V, 50HZ, single phase

-

- 502B Salted Duck Egg Separator

Capacity: 30,000 eggs/hour

Function: Water bath loading, ordering, Egg Breaking, Egg Yolk Separating from Egg White

As eggs are one of the most versatile ingredients demanded in the food industry, we at Zenyer have dedicated ourselves to making your business more profitable with egg processing equipment since its establishment in 1997. We are able to deliver turnkey solutions with our innovative products such as our egg graders, egg cleaning machines, egg separators and egg packing machines. Whether you want to set up a new egg processing plant or need to optimize your manufacturing facilities, Zenyer as a professional egg processing machine manufacturer can offer you solutions for all of your egg processing problems.

Videos