Egg Grading Machine, Egg Sorting Machine

Farmers classify their eggs by their weight, interior, and exterior quality at the time it is packed. During grading, the eggs are sorted according to the weight and are placed large-end up in their cartons for longer storage. Candling during the grading process can also help with quality checking. That's why egg processing begins with egg grading. ZENYER has focused on the design of various egg graders based on different egg processing needs in the industry. We are here to provide you with the best fit equipment with capacity from 4,000 eggs/hour up to 30,000 eggs/hour to help you achieve better production efficiency.

ZENYER focuses on designing durable equipment with simple structures. The following are types of egg graders in which sorting is done through mechanical weighing scaling, and the precision is perfectly controlled within ±1 gram. These machines use less than 400W of power, take up less space, and weigh less than traditional equipment. Our egg graders feature low fault rates and very little maintenance is needed.

-

- 101A Egg Grader Capacity: 4,000 eggs/hour

-

- 101B Egg Grader Capacity: 4,000 eggs/hour

-

- 101BS Egg Grader Capacity: 4,000 eggs/hour

-

- 102A Egg Grader Capacity: 5,400 eggs/hour

-

- 102B Egg Grader Capacity: 5,400 eggs/hour

-

- 102BS Egg Grader Capacity: 5,400 eggs/hour

-

- 102BP Egg Grader Capacity: 5,000 eggs/hour

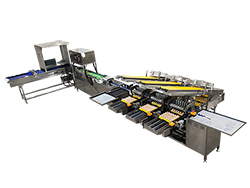

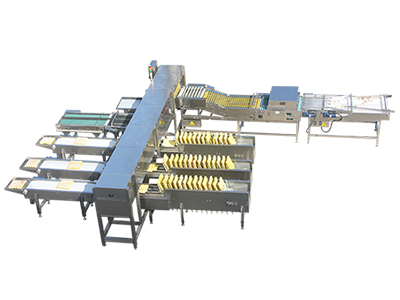

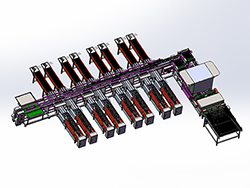

If you have higher requirements on the capacity and quality of your egg production, ZENYER provides egg graders that function with more automation. This type of egg grader sorts through an electronic sensor weighing scale and all steps are completely automatic from egg loading to tray filling. Gentle operation is guaranteed on each egg. By using egg graders, the growth and spread of bad bacteria is prevented and the cracking rate is kept at nearly 0%.

-

- 104A Egg Grader Capacity: 10,000 eggs/hour

-

- 104B Egg Grader Capacity: 10,000 eggs/hour

-

- 107 Egg Grader Capacity: 20,000 eggs/hour

-

- 109 Egg Grader Capacity: 30,000 eggs/hour.

-

- 111 Egg Grader Capacity: 60,000 eggs/hour

Features

Zenyer 104A and 104B egg grader can load 30 eggs at a time by using a vacuum egg lifter, the Zenyer 107 and 109 egg grader can connect with a rod conveyor which connects to the chicken shed, the eggs will flow into the egg grader smoothly. Ideally, connect the Zenyer 615 automatic vacuum loader with the 107 or 109 egg grader, which makes egg loading much easier and more efficient.

All egg graders use 6 rows of LED light to perform candling inspection to detect any leaks, dirt and cracks. A candling box and mirror can also be equipped for better inspection results.

Zenyer 104A, 104B, 107 and 109 type egg graders are all equipped with a color touchscreen PLC control system. Key features include:

① Adjusting grading settings, weighing precision correction;

② Sum up total capacity per shift and per grade;

③ Malfunction alarm and display;

④ Self-diagnosis system.

ZENYER manufactures a series of egg processing equipment with different functions. They are available for flexible assembly line designs, including egg graders, egg washers, egg printers, etc.

Video