- Home

- Products

- Egg Grader

- 109 Egg Grader

109 Egg Grader (30,000 EGGS/HOUR)

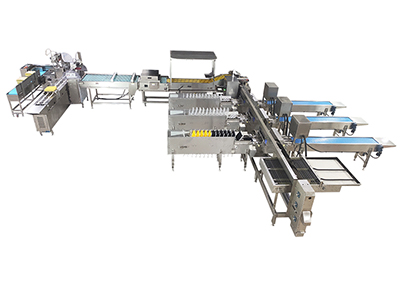

ZENYER 109 egg grader is made of strong quality stainless steel for great durability, corrosion resistance and hygiene. This egg grading model is featured with a digital touchscreen and PLC control system.

It grades eggs into 6 grades. Eggs are weighed by an electronic scale with an accuracy of within ±1 gram and a capacity of 30,000 eggs/hour. The 109 egg grader can be paired with an auto packer, and also be attached with a rod conveyor which directly connects to a chicken shed for egg loading.

You could also attach a 204A egg washer to form the 304A egg processing line with the same capacity but with added egg cleaning capabilities as well.

| Product name | Egg grader |

| Product code | 109 |

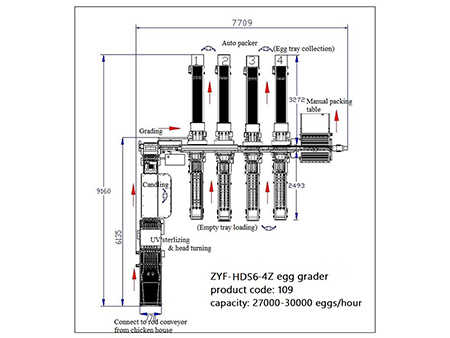

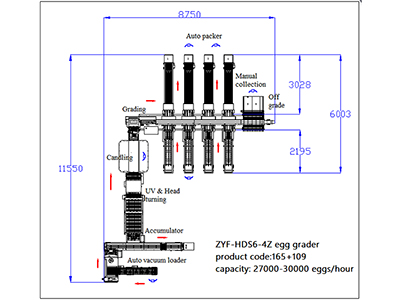

| Model | ZYF-HDS6-4Z |

| Capacity | 30,000 eggs/hour |

| Grading accuracy | ±1 gram |

| Grade* | 6 |

| Power* | 7.5 KW, 50HZ |

| Voltage* | 380V, 3-phase |

| Dimension (L*W*H) | 7.7*8.3*2 M |

| Net weight* | 1500KG |

| Gross weight* | 2100KG |

| Functions | Accumulator, head turning & candling, grading & counting, auto-packer, manual collection table and optional automatic vacuum loader and egg printer |

Notes

* Grade, power, net weight and gross weight are calculated according to the floor plan above.

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

- Auto vacuum loader (optional)

- Egg accumulator

- Automatic head turning

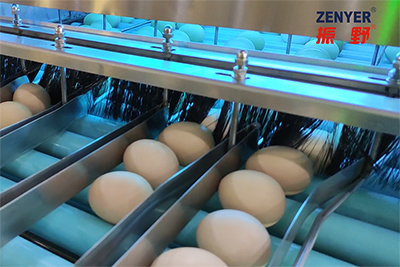

- Candling

- Grading (electronic sensor weighing) & counting

- Auto packer

- Egg printing (optional)

- Manual collection table

Ideally, connect the Zenyer 615 auto vacuum loader with the 109 egg grader. Making egg loading more easier and efficient.

You can put a stack of eggs (no more than 6 trays per stack) on the conveyor manually, the conveyor will then send the eggs under the 30-egg lifter head.

1. Head 1 sucks the whole tray of eggs (including the tray itself) and transfer them onto the single tray conveyor. When it arrives under the 30-egg lifter head.

2. Then head 2 will suck 30 eggs up from the tray and transfer the eggs onto the accumulator of the egg grader, the empty tray will be stacked automatically at the end of conveyor. You can take the whole stack of empty trays away manually.

Eggs are weighed electronically and graded into 6 grades.

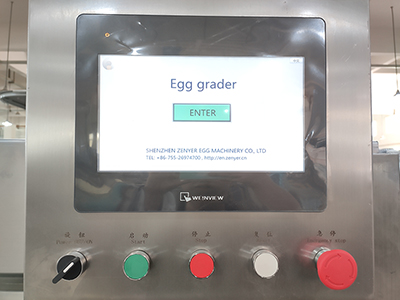

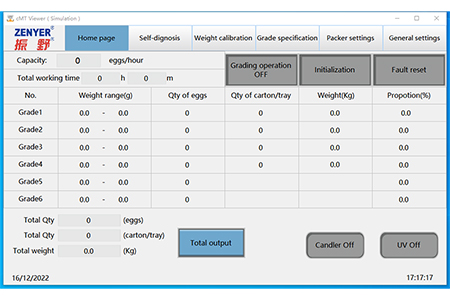

The 109 egg grader is equipped with a control panel with a color touchscreen and physical buttons as well, you can set the grading specification and calibrate the grading accuracy through the touchscreen. It has a self-diagnosis system, which diagnoses any malfunctions that may occur.

It has a counting function as well, you can check how many eggs of each grade and total output per shift have been processed.

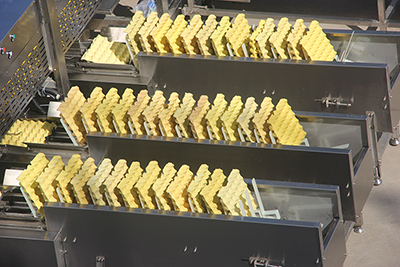

Each automatic packer includes a dropset unit, tray stacker and egg tray collection conveyor. Empty cartons/trays need to be manually placed in the stacker, allowing the stacker to transport the empty trays to where the eggs will drop from. The egg dropset unit drops the eggs into 5*6 egg trays automatically. The conveyor will transport the egg cartons/trays to the end.

Each auto packer can pack one size of egg cartons/trays. This machine can, in total, be equipped with 4 auto packers.

ZENYER 406H egg printer (6-print head) is an optional attachment on each egg tray collection conveyor after the trays filling process, to print the company name and logo, date, and Julian date, etc. on eggs.

Shenzhen ZENYER Egg Machinery Co., Ltd.

Add.: 136, Jiangshi Road, Matian Street, Guangming District, Shenzhen 518106, China

Tel.: +86-755-26974700 / 26974701

Fax: +86-755-26974358

Email: office@zenyer.cn

WhatsApp: +86-13823737025

Wechat: +8618038158337

+8618018763375