- Home

- Products

- Egg Lifter & Loader

- 605A Egg Accumulator

605A Egg Accumulator

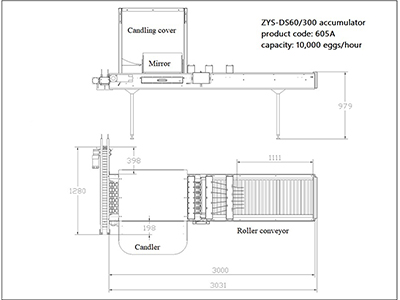

The 605A egg accumulator is equipped with a candling booth. It utilizes the 602 vacuum egg lifter to transfer 30 eggs onto the 605A accumulator at a time. When eggs pass through the candling booth, poor quality eggs can be inspected through the LED light and manually removed. Then the accumulator would direct 6 lines of eggs into 1 line and transfer the eggs onto single conveyor egg washer nicely with no cracking.

| Model | ZYS-DS60/240 |

| Product code | 605A |

| Power* | 398W, 50HZ |

| Voltage* | 220-240V, single phase Or 380-415V 3-phase |

| Dimension(L* W* H) | 3.03*1.28*2.0 M |

| Net weight* | 200 kg |

| Gross weight* | 350 kg |

| Function | Roller conveyor & candling & orientator and optional vacuum egg lifter |

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

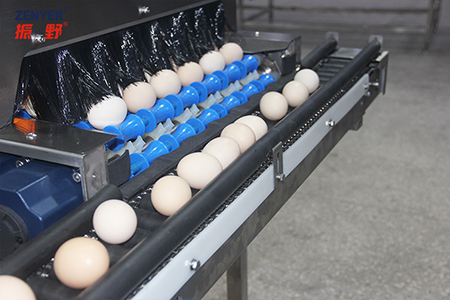

- Roller conveyor

- Candling booth

- Orientator

- Control panel of accumulator

Loading 30 eggs at a time on the 6-row rollers of conveyor via the Zenyer 602 vacuum egg lifter.

There are 2 control panels on the accumulator, one manages the speed of the roller conveyor and the other manages the speed of the orientator. The up arrow increases the speed while the down arrow decreases the speed. This function helps adjust the accumulator and orientator to match the speed of any other machines it is working with.

Shenzhen ZENYER Egg Machinery Co., Ltd.

Add.: 136, Jiangshi Road, Matian Street, Guangming District, Shenzhen 518106, China

Tel.: +86-755-26974700 / 26974701

Fax: +86-755-26974358

Email: office@zenyer.cn

WhatsApp: +86-13823737025

Wechat: +8618038158337

+8618018763375