- Home

- Products

- Egg Processing Line

- 302BS Egg Processing Line

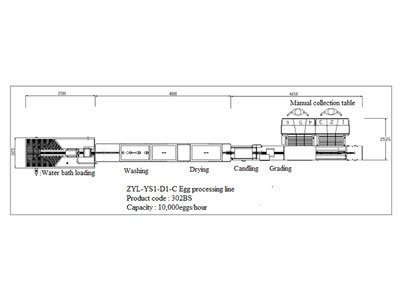

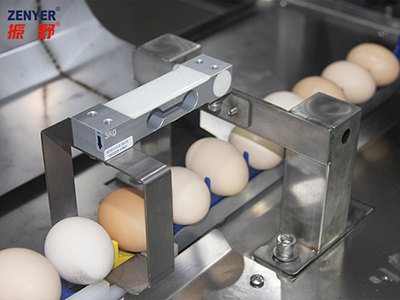

302BS Duck Egg Processing Line with Water Bath Loading & Washing & Grading (10,000 EGGS/HOUR)

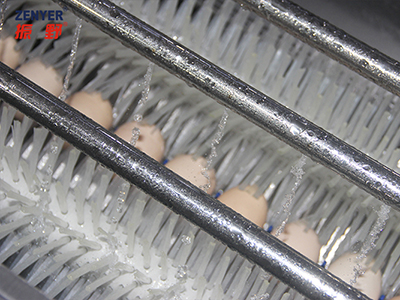

ZENYER 302BS egg processing line is comprised of the 202B egg washer and the 104B egg grader, and includes water bath loading, washing, drying, candling, grading & counting and manual collection. It has an adjustable capacity and can reach maximum capacity of 10,000 eggs/hour.

The water bath loading not only saves time but also minimizes egg cracks by using buoyancy.

This egg processing line is specially designed for DUCK egg processing, and the processing line ends up with packing washed eggs manually.

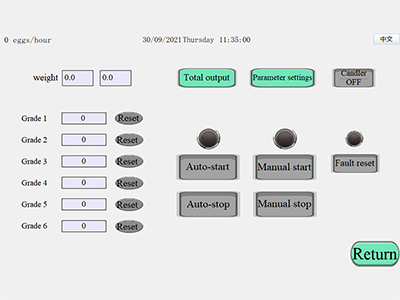

The 302BS egg processing line has a PLC control system with a touch screen, enabling you to easily set the grading specifications, calibrate the accuracy, accumulate quantities, and alarm and diagnose any malfunctions that may occur.

| Product code | Duck egg processing line |

| Product code | 302BS |

| Model | ZYL-YS1-D1-P |

| Capacity | 10,000 eggs/hour |

| Main material | Stainless steel |

| Power* | 12.43KW |

| Voltage* | 380V, 50Hz, 3-phase |

| Dimension (L*W*H) | 11.9*3.4*2 M |

| Net weight* | 700KG |

| Gross weight* | 1350KG |

| Function | Water bath loading, washing , drying, candling, grading & counting and manual collection table |

Notes

* Grade, power, net weight and gross weight are calculated according to the floor plan above.

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

- Water bath loading

- Washing

- Drying

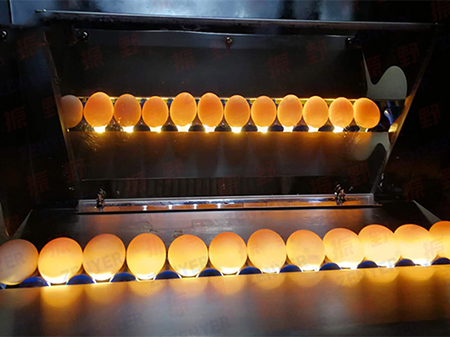

- Candling

- Grading & counting

- Manual collection table

Shenzhen ZENYER Egg Machinery Co., Ltd.

Add.: 136, Jiangshi Road, Matian Street, Guangming District, Shenzhen 518106, China

Tel.: +86-755-26974700 / 26974701

Fax: +86-755-26974358

Email: office@zenyer.cn

WhatsApp: +86-13823737025

Wechat: +8618038158337

+8618018763375